What are the Popular Models of Resistor Power?

I. Introduction

Resistors are fundamental components in electrical engineering, serving as the backbone of countless electronic circuits. At the heart of their functionality lies the concept of resistor power, which is crucial for understanding how resistors operate under various conditions. This article delves into the popular models of resistor power, exploring their characteristics, applications, and the factors that influence their performance.

II. Understanding Resistor Power

A. Basic Concepts of Resistance and Power

To grasp the significance of resistor power, one must first understand the basic principles of resistance and power in electrical circuits.

1. **Ohm's Law** states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. Mathematically, it is expressed as:

\[

V = IR

\]

2. **Power Calculation** is essential for determining how much energy a resistor can handle without failing. The power (P) dissipated by a resistor can be calculated using several formulas:

- \( P = \frac{V^2}{R} \)

- \( P = I^2R \)

- \( P = IV \)

These equations highlight the relationship between voltage, current, resistance, and power, forming the foundation for understanding resistor power ratings.

B. Types of Resistor Power Ratings

Resistor power ratings are categorized into different types based on their operational characteristics:

1. **Continuous Power Rating** refers to the maximum power a resistor can dissipate continuously without overheating.

2. **Pulsed Power Rating** indicates the maximum power a resistor can handle for short durations, which is crucial in applications involving transient signals.

3. **Derating Factors** are applied to account for environmental conditions, such as temperature and humidity, which can affect a resistor's performance.

III. Popular Models of Resistor Power

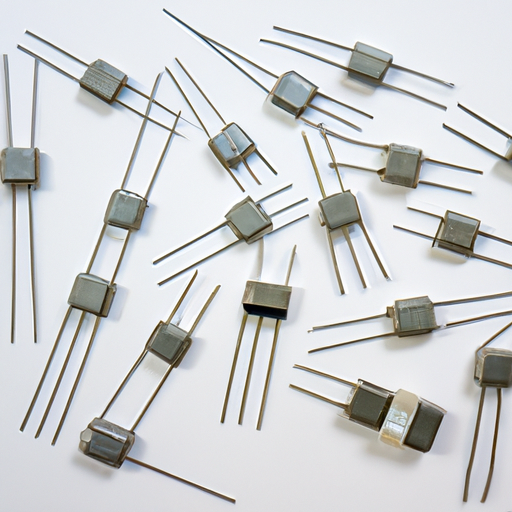

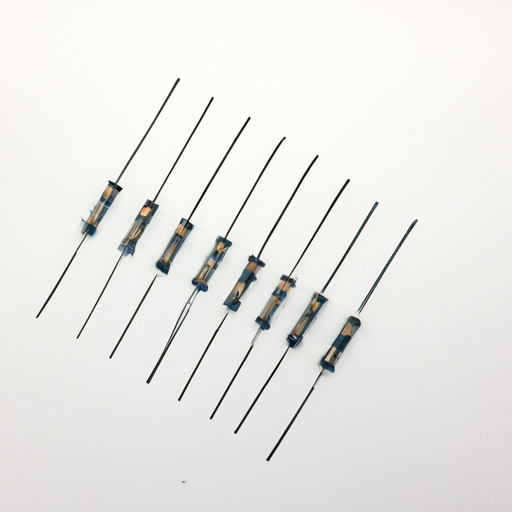

A. Carbon Composition Resistors

1. **Characteristics**: Carbon composition resistors are made from a mixture of carbon particles and a binding resin. They are known for their high energy absorption and ability to withstand high voltage spikes.

2. **Applications**: Commonly used in audio equipment, power supplies, and general-purpose applications.

3. **Advantages and Disadvantages**: They are inexpensive and can handle high energy pulses, but they have poor stability and tolerance compared to other types.

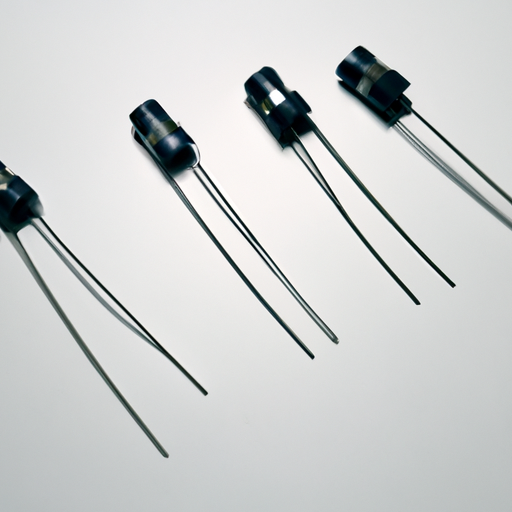

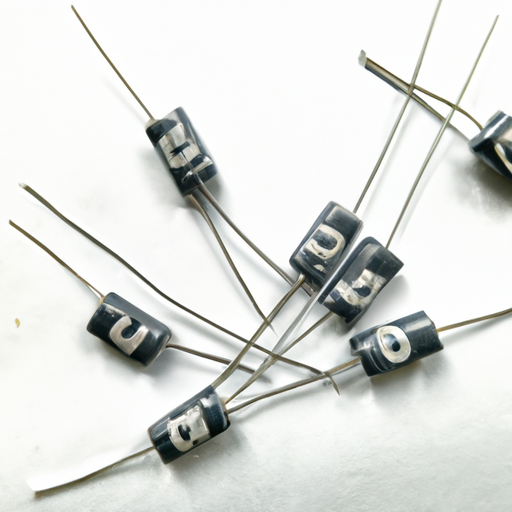

B. Metal Film Resistors

1. **Characteristics**: Metal film resistors are constructed by depositing a thin layer of metal onto a ceramic substrate. They offer high precision and stability.

2. **Applications**: Widely used in precision circuits, such as instrumentation and audio applications.

3. **Advantages and Disadvantages**: They provide excellent temperature stability and low noise, but can be more expensive than carbon composition resistors.

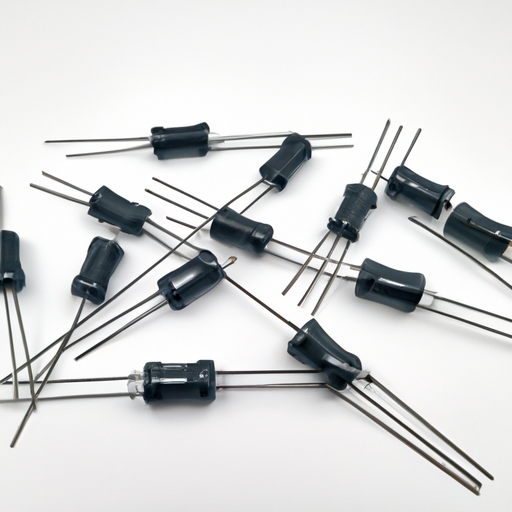

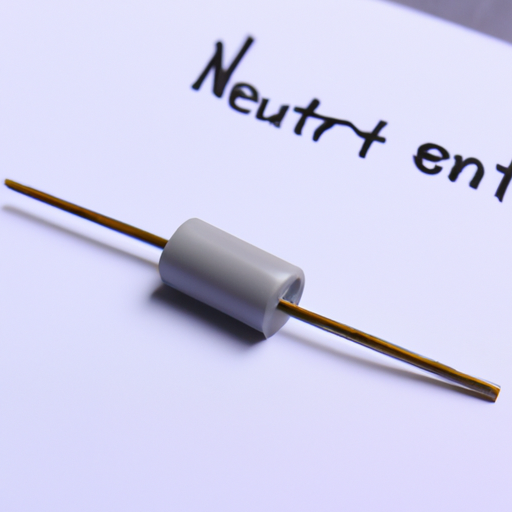

C. Wirewound Resistors

1. **Characteristics**: Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. They can handle high power levels and have low inductance.

2. **Applications**: Ideal for power applications, such as power supplies and motor control circuits.

3. **Advantages and Disadvantages**: They are robust and can dissipate significant power, but they can be bulky and have a limited frequency response.

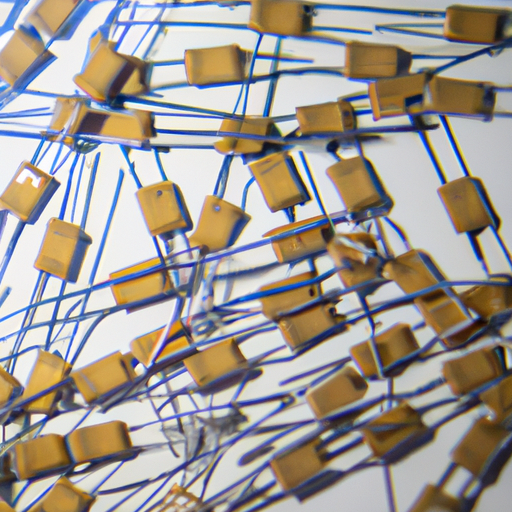

D. Thick Film Resistors

1. **Characteristics**: Thick film resistors are made by printing a resistive paste onto a substrate and then firing it to create a solid layer. They are cost-effective and versatile.

2. **Applications**: Commonly used in surface-mount technology (SMT) and consumer electronics.

3. **Advantages and Disadvantages**: They are inexpensive and suitable for mass production, but they may have higher noise levels and lower precision compared to thin film resistors.

E. Thin Film Resistors

1. **Characteristics**: Thin film resistors are created by depositing a very thin layer of resistive material onto a substrate. They offer high precision and low temperature coefficients.

2. **Applications**: Used in high-precision applications, such as medical devices and aerospace electronics.

3. **Advantages and Disadvantages**: They provide excellent stability and low noise, but are generally more expensive than thick film resistors.

F. Power Resistors

1. **Characteristics**: Power resistors are designed to handle high power levels and are often constructed with materials that can dissipate heat effectively.

2. **Applications**: Used in applications requiring high power dissipation, such as braking systems in electric vehicles and industrial machinery.

3. **Advantages and Disadvantages**: They can handle significant power loads and are durable, but they can be larger and more expensive than standard resistors.

IV. Factors Influencing Resistor Power Ratings

Several factors can influence the power ratings of resistors, affecting their performance in various applications:

A. Temperature Coefficient

The temperature coefficient indicates how much a resistor's resistance changes with temperature. A low temperature coefficient is desirable for applications requiring stability over a range of temperatures.

B. Voltage Rating

The voltage rating of a resistor determines the maximum voltage it can handle without breaking down. Exceeding this rating can lead to failure, making it crucial to select resistors with appropriate voltage ratings for specific applications.

C. Frequency Response

The frequency response of a resistor affects its performance in AC circuits. Some resistors may exhibit inductance or capacitance at higher frequencies, impacting their effectiveness in high-frequency applications.

D. Environmental Considerations

Factors such as humidity, altitude, and exposure to chemicals can affect a resistor's performance. Selecting resistors that can withstand specific environmental conditions is essential for ensuring reliability.

V. Applications of Resistor Power Models

Resistor power models find applications across various industries, including:

A. Consumer Electronics

In devices like televisions, smartphones, and audio systems, resistors play a critical role in signal processing and power management.

B. Industrial Equipment

Resistors are used in machinery for controlling motors, managing power supplies, and ensuring safety in electrical systems.

C. Automotive Applications

In modern vehicles, resistors are essential for managing power in electronic control units, sensors, and infotainment systems.

D. Telecommunications

Resistors are integral to communication devices, ensuring signal integrity and managing power in transmission lines.

E. Medical Devices

In medical equipment, precision resistors are crucial for accurate measurements and reliable operation, impacting patient safety and care.

VI. Future Trends in Resistor Technology

As technology advances, several trends are shaping the future of resistor technology:

A. Advancements in Materials

New materials are being developed to enhance the performance of resistors, including nanomaterials that offer improved stability and lower noise levels.

B. Miniaturization and Integration

The trend towards smaller electronic devices is driving the need for miniaturized resistors that can be integrated into compact circuits without sacrificing performance.

C. Smart Resistors and IoT Applications

With the rise of the Internet of Things (IoT), smart resistors that can monitor and adjust their performance in real-time are becoming increasingly important for smart devices and systems.

VII. Conclusion

In summary, understanding the popular models of resistor power is essential for anyone involved in electrical engineering or electronics design. Each type of resistor has its unique characteristics, advantages, and applications, making it crucial to choose the right model for specific needs. As technology continues to evolve, advancements in materials and design will further enhance the performance and capabilities of resistors, ensuring their relevance in modern electronics.

VIII. References

- Academic Journals

- Industry Standards

- Manufacturer Specifications

- Online Resources and Tutorials

This comprehensive overview of resistor power models provides a solid foundation for understanding their importance in various applications and the factors that influence their performance. By selecting the appropriate resistor model, engineers and designers can ensure the reliability and efficiency of their electronic systems.

2025-03-01