The Role of Resistor Factory Products in Practical Applications

I. Introduction

Resistors are fundamental components in electronic circuits, serving the essential function of controlling the flow of electric current. By providing resistance, they help to manage voltage levels, protect sensitive components, and ensure the proper functioning of devices. The importance of resistors cannot be overstated, as they are integral to virtually every electronic device we use today, from smartphones to medical equipment. This blog post will explore the role of resistor factory products in various practical applications, highlighting their types, manufacturing processes, and the challenges and future trends in resistor technology.

II. Types of Resistors

Resistors come in various types, each designed for specific applications and performance requirements. Understanding these types is crucial for selecting the right resistor for a given task.

A. Fixed Resistors

Fixed resistors have a predetermined resistance value that does not change. They are widely used in electronic circuits.

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a relatively high tolerance and are less stable over time.

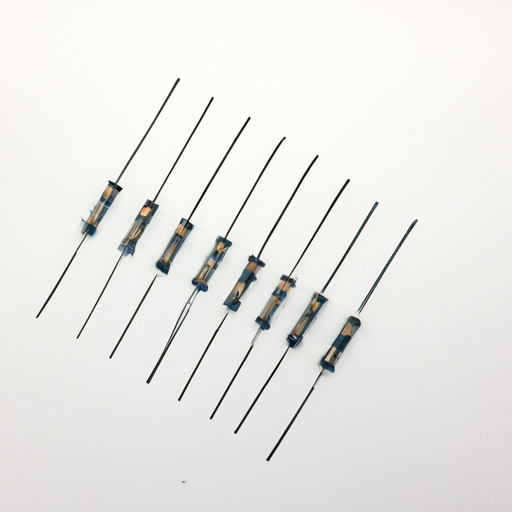

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better precision and stability compared to carbon composition resistors, making them suitable for applications requiring high accuracy.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power applications.

B. Variable Resistors

Variable resistors allow for adjustable resistance, making them versatile components in many applications.

1. **Potentiometers**: These are commonly used for volume control in audio devices and as adjustable voltage dividers in various circuits.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are often used in applications requiring variable resistance, such as in light dimmers.

C. Specialty Resistors

Specialty resistors are designed for specific functions and applications.

1. **Thermistors**: These temperature-sensitive resistors change resistance with temperature variations, making them ideal for temperature sensing and control.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure, commonly used in light-sensing applications.

3. **Varistors**: These voltage-dependent resistors protect circuits from voltage spikes by changing resistance in response to voltage changes.

III. Manufacturing Process of Resistors

The manufacturing process of resistors involves several steps, from selecting raw materials to quality control measures.

A. Raw Materials Used

1. **Conductive Materials**: The choice of conductive materials, such as carbon, metal films, or metal wires, significantly impacts the resistor's performance and characteristics.

2. **Insulating Materials**: Insulating materials, such as ceramics or plastics, are used to encase the resistive element, ensuring safety and stability.

B. Production Techniques

1. **Film Deposition**: In the production of metal film resistors, a thin layer of metal is deposited onto a substrate using techniques like sputtering or evaporation.

2. **Wire Winding**: For wirewound resistors, a precise winding process is employed to ensure uniform resistance and performance.

3. **Sintering**: This process involves heating materials to create a solid mass, often used in the production of ceramic-based resistors.

C. Quality Control Measures

1. **Testing for Resistance Values**: Each resistor is tested to ensure it meets specified resistance values and tolerances.

2. **Environmental Testing**: Resistors undergo environmental testing to assess their performance under various conditions, ensuring reliability in real-world applications.

IV. Applications of Resistor Factory Products

Resistor factory products find applications across a wide range of industries, each with unique requirements.

A. Consumer Electronics

In consumer electronics, resistors play a crucial role in audio devices, televisions, and computers. They help manage signal levels, protect components, and ensure optimal performance.

B. Automotive Industry

In the automotive sector, resistors are essential in engine control units, where they help regulate fuel injection and ignition timing. They are also vital in safety systems, such as airbags and anti-lock braking systems, ensuring reliable operation.

C. Industrial Equipment

Resistors are integral to automation and control systems in industrial equipment. They help manage power levels and ensure the proper functioning of machinery, contributing to efficiency and safety.

D. Medical Devices

In the medical field, resistors are critical in diagnostic equipment, such as ECG machines, where they help process signals accurately. They also play a role in therapeutic devices, ensuring safe and effective treatment.

E. Telecommunications

In telecommunications, resistors are used in signal processing and network equipment. They help manage signal integrity and ensure reliable communication, which is essential in today’s interconnected world.

V. Challenges in Resistor Manufacturing

Despite their importance, resistor manufacturing faces several challenges.

A. Demand for Miniaturization

As electronic devices become smaller and more compact, the demand for miniaturized resistors has increased. Manufacturers must innovate to produce smaller components without compromising performance.

B. Need for High Precision and Tolerance

With the growing complexity of electronic circuits, there is a heightened need for resistors with high precision and tight tolerances. Meeting these demands requires advanced manufacturing techniques and quality control measures.

C. Environmental Regulations and Sustainability

Manufacturers must navigate stringent environmental regulations and strive for sustainable practices. This includes using eco-friendly materials and processes to minimize environmental impact.

D. Competition and Market Dynamics

The resistor market is highly competitive, with numerous manufacturers vying for market share. Companies must continuously innovate and improve their products to stay relevant.

VI. Future Trends in Resistor Technology

The future of resistor technology is promising, with several trends shaping its development.

A. Advancements in Materials Science

Research in materials science is leading to the development of new conductive and insulating materials, enhancing resistor performance and reliability.

B. Development of Smart Resistors

Smart resistors, capable of adjusting their resistance based on external conditions, are emerging. These components can improve energy efficiency and performance in various applications.

C. Integration with IoT and Smart Devices

As the Internet of Things (IoT) continues to grow, resistors will play a vital role in smart devices, enabling connectivity and functionality.

D. Innovations in Manufacturing Processes

Advancements in manufacturing processes, such as 3D printing and automation, are expected to revolutionize resistor production, making it more efficient and cost-effective.

VII. Conclusion

Resistor factory products are indispensable in modern technology, playing a crucial role in various applications across multiple industries. From consumer electronics to medical devices, resistors ensure the proper functioning of countless devices we rely on daily. As technology continues to evolve, the importance of resistors will only grow, with exciting advancements on the horizon. The ongoing relevance of resistors in modern technology underscores the need for continued innovation in their manufacturing and application, ensuring they meet the demands of the future.

VIII. References

1. Academic journals and articles on resistor technology and applications.

2. Industry reports detailing market trends and challenges in resistor manufacturing.

3. Manufacturer specifications and guidelines for various types of resistors.

This comprehensive overview highlights the critical role of resistor factory products in practical applications, emphasizing their significance in the ever-evolving landscape of technology.