What are the Latest Resistors? What are the Procurement Models of Equipment Components?

I. Introduction

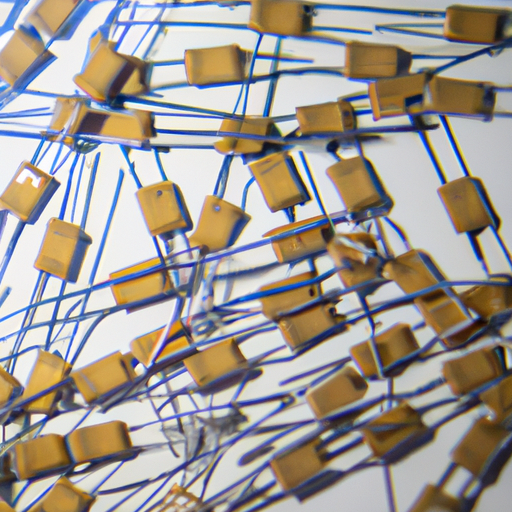

Resistors are fundamental components in electronic circuits, serving the critical function of controlling current flow. They are essential for protecting sensitive components, dividing voltages, and setting bias points in various applications. Over the years, the evolution of resistors has been marked by advancements in materials, manufacturing techniques, and applications, reflecting the rapid pace of technological innovation in the electronics industry. This article aims to explore the latest advancements in resistors and the procurement models for equipment components, providing insights into how these elements are shaping the future of electronics.

II. Latest Advancements in Resistors

A. Types of Resistors

Resistors can be broadly categorized into three main types: fixed, variable, and specialty resistors.

1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in circuits for current limiting and voltage division.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow for adjustable resistance, making them ideal for applications like volume controls and tuning circuits.

3. **Specialty Resistors**: This category includes precision resistors, current sensing resistors, and high-voltage resistors, designed for specific applications requiring unique characteristics.

B. Innovations in Resistor Technology

Recent innovations in resistor technology have led to the development of various types of resistors, each with distinct advantages and applications.

1. **Thin Film Resistors**: These resistors are made by depositing a thin layer of resistive material on a substrate. They offer high precision, stability, and low temperature coefficients, making them suitable for high-performance applications in telecommunications and instrumentation.

2. **Thick Film Resistors**: Constructed using a thicker layer of resistive material, thick film resistors are known for their robustness and cost-effectiveness. They are commonly used in consumer electronics and automotive applications.

3. **Wirewound Resistors**: These resistors are made by winding a metal wire around a ceramic or fiberglass core. They can handle high power levels and are often used in power supplies and industrial applications.

4. **Carbon Composition Resistors**: Although less common today, these resistors are made from a mixture of carbon and a binding material. They are known for their high energy absorption and are still used in specific applications where high pulse handling is required.

5. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer excellent stability and low noise, making them ideal for precision applications in audio and measurement equipment.

C. Emerging Trends

The resistor industry is witnessing several emerging trends that are shaping the future of electronic components.

1. **Miniaturization and Surface Mount Technology (SMT)**: As devices become smaller and more compact, the demand for miniaturized resistors has increased. SMT resistors are designed for automated assembly processes, allowing for higher density circuit designs.

2. **High-Temperature and High-Power Resistors**: With the rise of electric vehicles and renewable energy systems, there is a growing need for resistors that can operate under extreme conditions. High-temperature and high-power resistors are being developed to meet these demands.

3. **Smart Resistors and IoT Integration**: The integration of resistors with smart technologies and the Internet of Things (IoT) is becoming more prevalent. Smart resistors can provide real-time data on their performance, enabling predictive maintenance and improved efficiency.

4. **Environmental Considerations and Eco-Friendly Materials**: As sustainability becomes a priority, manufacturers are exploring eco-friendly materials and processes for resistor production. This includes the use of recyclable materials and reducing the carbon footprint of manufacturing processes.

III. Key Manufacturers and Market Trends

A. Leading Manufacturers of Resistors

The resistor market is characterized by several key players who are driving innovation and product development. Major manufacturers include:

1. **Vishay Intertechnology**: Known for its extensive range of resistors, Vishay is a leader in precision and specialty resistors.

2. **Yageo Corporation**: A global leader in passive components, Yageo offers a wide variety of resistors, including thin film and thick film options.

3. **TE Connectivity**: TE Connectivity provides a range of resistors designed for automotive and industrial applications, focusing on high reliability and performance.

4. **Panasonic**: With a strong emphasis on innovation, Panasonic produces a variety of resistors, including those designed for high-temperature applications.

B. Market Trends

The resistor market is influenced by several key trends:

1. **Demand for High-Precision Resistors**: As industries such as telecommunications and medical devices require greater accuracy, the demand for high-precision resistors is on the rise.

2. **Growth in Automotive and Consumer Electronics Sectors**: The increasing complexity of electronic systems in vehicles and consumer devices is driving the need for advanced resistor technologies.

3. **Impact of Global Supply Chain Dynamics**: The COVID-19 pandemic and geopolitical tensions have highlighted vulnerabilities in global supply chains, prompting manufacturers to rethink their sourcing and procurement strategies.

IV. Procurement Models for Equipment Components

A. Definition and Importance of Procurement Models

Procurement models refer to the strategies and processes organizations use to acquire goods and services. In the context of electronic components, effective procurement is crucial for ensuring quality, reliability, and cost-effectiveness.

B. Traditional Procurement Models

1. **Direct Purchasing**: This model involves purchasing components directly from manufacturers or suppliers. It is straightforward but may lack flexibility in terms of pricing and availability.

2. **Bulk Purchasing**: Organizations often buy components in bulk to take advantage of discounts. This model can lead to cost savings but requires careful inventory management.

3. **Just-In-Time (JIT) Procurement**: JIT procurement focuses on minimizing inventory levels by ordering components only as needed. This approach reduces holding costs but requires reliable suppliers to avoid production delays.

C. Modern Procurement Models

1. **E-Procurement**: The use of digital platforms for procurement has gained popularity. E-procurement offers benefits such as streamlined processes, improved transparency, and enhanced supplier collaboration. However, challenges include the need for robust cybersecurity measures.

2. **Vendor-Managed Inventory (VMI)**: In this model, suppliers manage the inventory levels of their products at the buyer's location. VMI can lead to reduced stockouts and improved supply chain efficiency, but it requires strong communication and trust between parties.

3. **Collaborative Procurement**: Organizations may collaborate with other companies to leverage collective buying power. This model can lead to cost savings and improved supplier relationships but may require more complex negotiations.

D. Factors Influencing Procurement Decisions

Several factors influence procurement decisions in the electronics industry:

1. **Cost Considerations**: Price remains a primary factor, but organizations must balance cost with quality and reliability.

2. **Quality and Reliability**: High-quality components are essential for ensuring the performance and longevity of electronic devices.

3. **Supplier Relationships**: Strong relationships with suppliers can lead to better terms, faster response times, and improved collaboration.

4. **Lead Times and Logistics**: Organizations must consider lead times and logistics when planning procurement to avoid production delays.

V. Case Studies

A. Successful Implementation of Modern Procurement Models

1. **Example from the Electronics Industry**: A leading electronics manufacturer adopted an e-procurement system to streamline its component sourcing process. By digitizing procurement, the company reduced lead times by 30% and improved supplier collaboration, resulting in significant cost savings.

2. **Example from the Automotive Industry**: An automotive company implemented a vendor-managed inventory model with its key suppliers. This collaboration led to a 20% reduction in inventory costs and improved production efficiency, allowing the company to respond more quickly to market demands.

B. Lessons Learned and Best Practices

Organizations can learn valuable lessons from these case studies, including the importance of embracing technology, fostering strong supplier relationships, and continuously evaluating procurement strategies to adapt to changing market conditions.

VI. Conclusion

In summary, the latest advancements in resistors reflect the ongoing evolution of technology in the electronics industry. From innovations in materials and manufacturing techniques to emerging trends like miniaturization and IoT integration, resistors continue to play a vital role in modern electronic devices. Additionally, understanding procurement models is essential for organizations seeking to optimize their sourcing strategies and ensure the reliability of their components. As the electronics landscape evolves, staying informed about advancements in resistors and procurement strategies will be crucial for success in this dynamic industry.

VII. References

A comprehensive list of academic papers, industry reports, and articles used for research, along with additional resources for further reading on resistors and procurement models, can be provided upon request.