Popular Spot Product Models of Wuhu Machine Tools in Stock

I. Introduction

A. Overview of Wuhu Machine Tools

Wuhu Machine Tools, established in the early 1990s, has emerged as a significant player in the machine tool industry. Located in Wuhu, Anhui Province, China, the company has built a reputation for producing high-quality, precision-engineered machinery. Over the years, Wuhu Machine Tools has expanded its product range and capabilities, becoming a trusted supplier for various industries, including automotive, aerospace, and electronics.

B. Purpose of the Article

This article aims to inform readers about the popular product models offered by Wuhu Machine Tools that are currently in stock. By highlighting these models, we will explore their significance in various industries and how they meet the evolving needs of manufacturers.

II. Understanding Wuhu Machine Tools

A. Company Background

Wuhu Machine Tools operates from a state-of-the-art facility equipped with advanced manufacturing technologies. The company prides itself on its core values of innovation, quality, and customer satisfaction. Its mission is to provide reliable and efficient machine tools that enhance productivity and precision in manufacturing processes.

B. Product Range

Wuhu Machine Tools offers a diverse range of machine tools, including CNC lathes, milling machines, grinding machines, and specialized equipment. These tools are designed to cater to various industries, ensuring that manufacturers have access to the right machinery for their specific applications.

III. Popular Product Models

A. Overview of Popular Models

The popularity of Wuhu Machine Tools' models can be attributed to several factors, including sales performance, customer reviews, and versatility in applications. Below are some of the most sought-after models currently in stock.

B. Detailed Descriptions of Specific Models

1. Model A: Wuhu CNC Lathe Series

The Wuhu CNC Lathe Series is renowned for its precision and efficiency. Equipped with advanced CNC technology, these lathes offer high-speed machining capabilities and exceptional accuracy. Key features include:

Specifications: Spindle speed up to 4000 RPM, maximum turning diameter of 300 mm, and a bed length of 1000 mm.

Applications: Ideal for producing complex parts in the automotive and aerospace industries, where precision is paramount.

2. Model B: Wuhu Vertical Milling Machine

The Wuhu Vertical Milling Machine is designed for versatility and ease of use. This model is perfect for both small-scale and large-scale production. Key features include:

Specifications: Table size of 1200 x 250 mm, spindle speed range of 50-3000 RPM, and a powerful 5 HP motor.

Applications: Commonly used in manufacturing components for electronics and machinery, this milling machine excels in producing intricate designs.

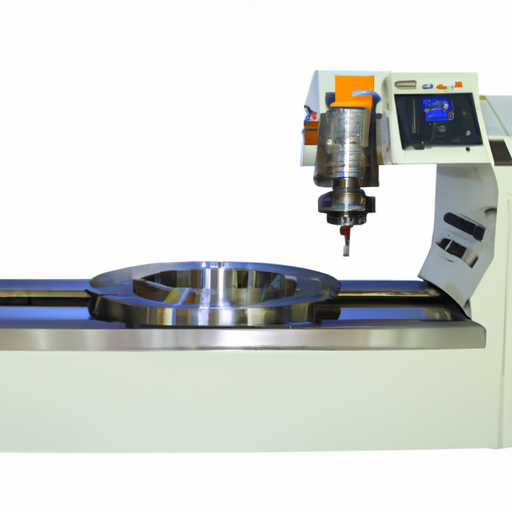

3. Model C: Wuhu Surface Grinding Machine

The Wuhu Surface Grinding Machine is a favorite among manufacturers looking for high-quality surface finishes. This model is known for its robust construction and user-friendly interface. Key features include:

Specifications: Grinding wheel diameter of 400 mm, table size of 600 x 300 mm, and a maximum grinding depth of 200 mm.

Applications: Widely used in the automotive and aerospace sectors for finishing parts that require a smooth surface.

4. Model D: Wuhu Horizontal Band Saw

The Wuhu Horizontal Band Saw is designed for efficient cutting of various materials. This model is particularly popular in metalworking and fabrication shops. Key features include:

Specifications: Cutting capacity of 300 mm in diameter, adjustable cutting speed, and a durable blade system.

Applications: Ideal for cutting metal bars and profiles, making it essential for construction and manufacturing industries.

5. Model E: Wuhu CNC Machining Center

The Wuhu CNC Machining Center is a versatile machine that combines milling, drilling, and tapping functions. This model is perfect for high-volume production. Key features include:

Specifications: Worktable size of 1000 x 500 mm, spindle speed of 12000 RPM, and a tool magazine capacity of 24 tools.

Applications: Commonly used in the production of complex components in the automotive and electronics industries.

IV. Key Features of Wuhu Machine Tools

A. Technological Advancements

Wuhu Machine Tools is at the forefront of technological advancements in the machine tool industry. The integration of automation and smart technology into their products enhances efficiency and precision. Features such as CNC controls and real-time monitoring systems allow for seamless operation and reduced downtime.

B. Durability and Reliability

The durability and reliability of Wuhu Machine Tools are evident in the materials used in their construction. High-quality steel and precision components ensure that these machines can withstand the rigors of continuous operation. Additionally, Wuhu offers comprehensive maintenance and support services to keep machines running smoothly.

C. Customization Options

Wuhu Machine Tools understands that different industries have unique requirements. As such, they offer customization options that allow manufacturers to tailor machines to their specific needs. This includes modifications for industry-specific solutions, ensuring that customers receive the best possible equipment for their applications.

V. Applications of Wuhu Machine Tools

A. Industries Utilizing Wuhu Products

Wuhu Machine Tools serves a wide range of industries, including:

Automotive: Precision machining for engine components and transmission parts.

Aerospace: Manufacturing of lightweight and durable components for aircraft.

Manufacturing: General machining for various industrial applications.

Electronics: Production of intricate parts for electronic devices.

B. Case Studies or Examples of Successful Implementations

One notable case study involves a leading automotive manufacturer that integrated Wuhu CNC Lathes into their production line. The result was a 30% increase in productivity and a significant reduction in machining errors, showcasing the effectiveness of Wuhu's technology in real-world applications.

VI. Customer Feedback and Market Reception

A. Reviews and Testimonials

Customer feedback for Wuhu Machine Tools has been overwhelmingly positive. Users frequently highlight the precision, reliability, and ease of use of the machines. However, some customers have noted areas for improvement, such as the need for more comprehensive training resources for new users.

B. Market Trends and Demand

Wuhu Machine Tools has maintained a strong market position, with increasing demand for their products. The company has successfully navigated challenges posed by global competition, thanks to its commitment to quality and innovation. Compared to competitors, Wuhu stands out for its customer service and customization options.

VII. Conclusion

A. Summary of Key Points

Wuhu Machine Tools has established itself as a leader in the machine tool industry, offering a diverse range of popular product models that cater to various sectors. The combination of advanced technology, durability, and customization options makes Wuhu a preferred choice for manufacturers.

B. Future Outlook for Wuhu Machine Tools

Looking ahead, Wuhu Machine Tools is poised for continued growth and innovation. The company is exploring new technologies, such as artificial intelligence and IoT integration, to further enhance its product offerings. As industries evolve, Wuhu is committed to meeting the changing needs of its customers, ensuring its place as a key player in the machine tool market.

VIII. References

A. Sources of Information

1. Wuhu Machine Tools Official Website

2. Industry Reports on Machine Tool Trends

3. Customer Testimonials and Reviews

B. Further Reading and Resources for Interested Readers

1. "The Future of Machine Tools: Trends and Innovations"

2. "Understanding CNC Technology: A Comprehensive Guide"

3. "The Role of Machine Tools in Modern Manufacturing"

This blog post provides a comprehensive overview of the popular product models of Wuhu Machine Tools, highlighting their features, applications, and market reception. By understanding these models, manufacturers can make informed decisions about the machinery that best suits their needs.